The Hidden Cost of AI Pilots that Never Scale

Plus a Free Downloadable AI Pilot Planning Worksheet at the Bottom

Every new beginning can feel like the Call to Adventure in a hero’s journey. There is an opportunity to succeed, disrupt the current way that business is accomplished and the ability to put a stamp on something bigger than yourself.

And, much like the hero’s journey, there comes a time that is referred to as “The Ordeal.” In a book, this is where there seem to be more failures than successes. The battles seem to be stacked against the heroine. The road seems long and particularly perilous.

AI Pilots, and any tech POC or Pilot, can feel like that. When you are in the thick of it and there seems to be an endless line of red tape, technological challenges, and sometimes the team loses sight as to where they are going. The problem is, many of these challenges are simply wrapped up and put onto a shelf.

According to a March 2025 article in CIO Magazine, 88% of AI pilots fail to reach production in spite of being declared “successful” during development. In a May report posted by McKinsey, the authors reported that the incentives that business leaders offer for many technology projects reward “technology delivery over business-wide value.”[McKinsey]

Much like the Hidden Costs of AI that I spoke about previously, there are additional costs associated with pilots that never scale. You know the ones: the business case is made (we will save X number of hours in productivity/manufacturing defects/lost revenue!), the team is assembled (yay!), and the initial POC is out the door. You take it up a notch and pilot this technology in a “real-world”, albeit managed, setting.

And then…it disappears.

The Manufacturing Example - Lead with the Numbers

I was speaking to a former colleague about an AI pilot that cost their company $500K to build and could have saved millions in manufacturing defects. The team spent eight months organizing 25 years of supplier data, training models, and creating a system that could instantly flag counterfeit parts and contamination risks.

The demo was flawless. The ROI projections were compelling. The system worked exactly as designed.

It's been sitting unused for 18 months.

That's $500K in direct development costs, plus roughly $200K in opportunity costs (the problems it could have solved), plus the ongoing cloud hosting fees they're still paying. Total sunk cost: over $700K and counting.

The Hidden Multiplier Effect

But here's what really hurts: this isn't an isolated incident. The same company has at least four other AI pilots in various stages of digital decay (each of these is someone’s pet project). Each of these projects has a valid outcome that the champion believes (and is correct in assuming) would help their business unit’s bottom line:

Customer sentiment analysis: $300K spent, 14 months on the shelf

Predictive maintenance: $450K invested, "pending deployment" for 10 months

Supply chain optimization: $275K built, waiting for "the right time to launch"

Quality control vision system: $380K developed, stalled in security review

Total sunk cost across five projects: $1.9 million. And they're not alone.

This pattern is a symptom of a larger issue: Industry data shows that more than 88% of AI pilots never reach production, according to Information Week. BCG puts successful pilot-to-production conversion at just 25%.

How do you factor an 88% failure rate into AI pilot ROI calculations?

This is a pretty frightening figure. I have to wonder how this is taken into account when considering the ROI of an AI pilot?

The Carrying Cost Trap

Every shelved pilot becomes a monthly subscription to failure:

Cloud hosting fees: $5-50K/month

Data storage and processing: $2-20K/month

License fees for ML platforms: $10-100K/month

Security compliance monitoring: $5-15K/month

Then there are the costs associated with the people and other harder-to-measure costs:

People time: DevOps engineers, data scientists, and compliance teams maintaining an idle system so it doesn’t fall completely out of readiness.

Process overhead: Periodic audits, access reviews, and patching, all billed to the cost center.

Opportunity cost: The infrastructure and talent tied up here can’t be used for live, revenue-generating systems.

A $500K pilot can easily cost $100K annually just sitting there, “Ready for Deployment.” That’s a 20% negative ROI each year before you even touch it again.

And the longer it sits, the worse it gets:

Data drift means your model accuracy quite degrades

Platform upgrades create compatibility headaches, making the eventual deployment costlier

Security posture erodes, leading to even more expensive remediation before it goes live

This is why the carrying cost isn’t just a financial nuisance, it’s a compounding liability. The longer you delay scaling, the higher the restart cost, and the lower the likelihood the project ever makes it to production.

The Expertise Decay Tax

The engineers who built your pilot? They’ve moved on.

The business stakeholders who championed it? Promoted or transferred.

The institutional knowledge that made it work? Faded into Slack history and forgotten meeting notes.

When a pilot sits idle, the team’s shared context – the decisions, shortcuts, and “we’ll fix that later” workarounds – evaporates. And when you finally dust it off, you’re not just re-deploying code: you’re reassembling a tribe.

Reactivating a year-old pilot often costs 40-60% of the original development budget just to get the team back up to speed.

Re-hiring or reassigning technical talent with the right skill mix

Onboarding them into a codebase that’s now stale and possibly incompatible with updated tools

Rebuilding trust with business users who have since redirected their focus

Revalidating assumptions with new leadership or shifting market conditions

And wait! There’s more!

Lost champions mean you may need to “sell” the project all over again to executives who weren’t there for the original business case.

New compliance standards might force additional work, even if the tech hasn’t changed.

Tooling shifts (cloud providers ML frameworks, data sources) can make parts of the solution obsolete, requiring partial or full rewrites.

You’re not just paying for the technology, you’re paying to rebuild the human infrastructure around it. Every month a pilot sits untouched increases the probability that the next person to touch it will say exactly what my friend told me over lunch the other day when she told me about the pilot she’s been asked to resurrect with a small team:

“We have to reverse engineer everything and half of the data, logic and models are out of date. We should just start over.”

How to Protect Against the Costs of Shelved AI Projects

Adjust the ROI Lens from “Pilot Success” to “Production Value”

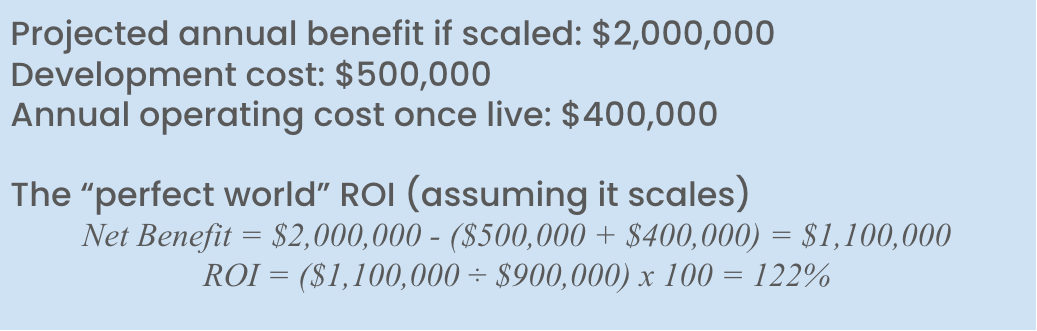

One of the last posts I discussed was about measuring the value of AI: the big ROI question. As a reminder:

ROI = (Net Benefit / Total Cost) x 100 (where Net Benefit = Total Benefits = Total Costs).

My question now has become: how do you factor in the cost of shelved AI projects into the ROI?

Most AI business cases stop at “Can we prove it works”” instead of “Will it work at scale?”

When you skip this risk factor, you’re overstating ROI. The fix is simple: add a conversion multiplier to adjust projected benefits based on your historical scale rate (or start conservative at 25% or less if you don’t have that historical data).

As an example:

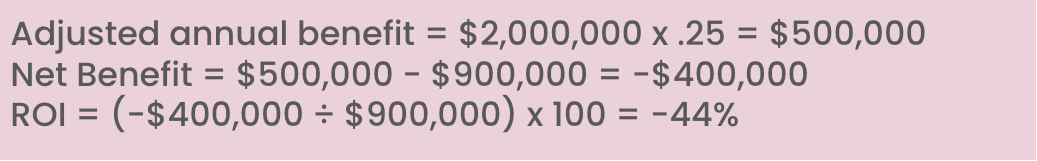

If only 25% of your “successful” pilots actually go live, multiply the benefit side of your ROI equation by 0.25 before comparing it to the costs.

So, a portfolio showing $5M in “projected benefits” suddenly looks more like $1.25M in realized benefits. And that gap forces harder, but better, decisions about where to invest to improve conversion odds.

Looks great until you factor in the reality that only 25% of pilots reach production in your organization.

Make the “Go/No-Go” Gate Explicit and Ruthless

When you quantify the multiplier effect, you make it easier to justify killing a pilot early if the scaling cost is too high or the expected value too low.

Add a formal "Production Viability” checkpoint between pilot and scale phases.

At the gate, require a refreshed risk and ROI analysis with the real scaling costs plugged in, if it doesn’t meet your hurdle rate then it is time to stop.

This prevents zombie projects that quietly consume budget and political capital.

How to Beat the Odds

Most AI pilots never make it past the demo stage — and the costs of stalling are far higher than most teams realize. Don’t let yours join the shelfware graveyard.

Download the AI Pilot Planning Worksheet — a free, practical tool to:

Build a solid business case from day one

Identify risks before they become roadblocks

Design for production so you crush the 25% success rate