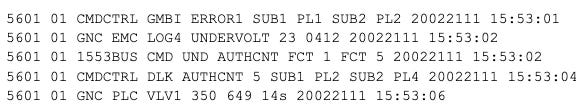

When I got my first job out of college, I was working on satellites for a large aerospace contractor. Specifically, I was responsible for developing machine learning algorithms to assist in testing and quality control of spacecraft prior to launch. The test bed system would generate massive logs of text data, overwhelming our technicians.

Here was our challenge: While obvious errors were easy to spot, subtle anomalies often got buried in the data. Finding these small issues early was crucial - the closer to (or after) launch you discovered a problem, the more expensive it became to fix.

The past few weeks, as part of my learning plan, I've been examining the manufacturing industry - specifically automotive manufacturing. Whether you're developing a satellite, a chipset, or a car, AI offers powerful benefits for quality control and inspection.

Why Quality Control Matters

A comprehensive 2021 study of AI in automotive manufacturing ranked visual quality control as one of the highest-value and most feasible AI applications. This insight is key to understanding why companies like BMW have strategically prioritized this use case. The study's findings validate their approach, placing visual quality control near the top in terms of both potential value and implementation feasibility.

This focus on visual inspection makes perfect sense. It’s a tedious but essential task—similar to analyzing those endless spacecraft logs I encountered early in my career. The challenge lies in our human tendency to miss subtle but critical details, especially when overwhelmed by repetitive tasks. This phenomenon is best illustrated by the fascinating Invisible Gorilla study conducted by psychologists Dan Simons and Christopher Chabris in 2010.

In their experiment, radiologists were asked to review CT scans for lung nodules. In one of the final images, the researchers embedded a “gorilla” graphic larger than any nodule. Astonishingly, 20 of the 24 radiologists didn’t notice it, despite intensely focusing on the scans. This wasn’t a failure of expertise but a limitation of human attention when facing repetitive, high-stakes work. This study mirrors the challenges facing visual quality control in manufacturing. If experts can overlook something as obvious as a gorilla, how often might they miss subtler defects like hairline fractures or microscopic material flaws?

BMW’s Path to Success

So how did BMW successfully deploy their AI system at scale? They took a smart, methodical approach:

Start with high-value, highly-feasible applications

BMW identified areas where AI could quickly demonstrate value with minimal risk. They focused initially on pressing/body shop applications where visual defects—such as scratches, dents, or misalignments—are mission-critical to the final product.Focused initially on pressing/body shop applications where visual defects are critical

Target specific pain points

A common challenge in manufacturing inspections is distinguishing real defects from superficial issues, like dust or oil marks. BMW trained their AI to differentiate between these, significantly reducing false positives.

Gradual expansion to complex tasks

Once the AI system proved successful in visual inspections, BMW expanded its applications to more intricate challenges, such as verifying model specifications and optimizing logistics.

Maintain consistent infrastructure and practices

A crucial factor in scaling AI initiatives is standardization. By keeping infrastructure and workflows consistent across teams and locations, BMW avoided the pitfalls of siloed data and fragmented systems.The Technical Innovation: Transfer Learning

Technical Innovation: Transfer Learning

One of BMW’s standout innovations was their use of transfer learning. Rather than building AI models from scratch—which typically requires vast amounts of training data—they repurposed pre-trained neural networks for their specific needs. This significantly reduced the data burden, as workers could train the system using just hundreds of real-world images from their production environments. The result? Faster deployment, higher accuracy, and reduced costs.

Transfer learning also democratized the technology. By enabling workers to directly contribute to training the system with minimal technical expertise, BMW turned AI from an intimidating black-box solution into a practical, user-friendly tool.

Putting People First

BMW’s approach to AI was as much about people as it was about technology. They recognized that quality control inspectors are skilled professionals, not replaceable cogs. By designing an AI system that was intuitive and easy to adopt, they empowered workers to focus on higher-value tasks, such as solving complex problems and refining processes.

This shift also alleviated the repetitive and often frustrating aspects of manual inspections, reducing burnout and fostering job satisfaction. It’s a compelling example of how AI can augment human expertise rather than replace it.

Measuring Success

While companies are often hesitant to share specific financial metrics, BMW's results speak for themselves:

Reduction in False Positives: By accurately distinguishing real defects from superficial marks, BMW eliminated unnecessary manual inspections

Improved Production Flow: Faster inspections meant fewer delays, directly benefiting revenue.

High Accuracy with Minimal Data: Achieving robust performance with just 100 images per condition demonstrated the power of focused, efficient training.

Enhanced Employee Productivity: Workers could spend more time on strategic, meaningful work instead of tedious inspections.

The implications are significant. Before this system, parts would be flagged as defective when they were actually fine, leading to:

Wasted labor hours on unnecessary inspections

Production delays costing revenue

Risk of real defects being dismissed as "probably just dust"

What's particularly impressive is achieving such sophisticated differentiation with such a small dataset - proving that smart implementation matters more than massive data collection.

Lessons for Other Industries

BMW’s journey mirrors lessons I’ve observed in other industries, like banking and even aerospace:

Start Where It Matters Most: Focus on high-value, high-feasibility applications to build momentum and demonstrate ROI early.

Empower Existing Teams: AI works best when it enhances human capabilities, not when it sidelines skilled workers.

Address Tedious Work First: Automating repetitive tasks frees employees to tackle creative, strategic challenges.

These principles transcend industry boundaries. Whether you’re building satellites, cars, or financial systems, a thoughtful, human-centered approach to AI implementation is the key to lasting success.

I’m taking the week off next week and I hope you all have an enjoyable holiday with friends and family, whatever you celebrate. I’ll be coming back with some frameworks that I have been working on that may support you in your AI journey.